商品描述:

商品屬性

商品描述:

商品屬性

■可作斜度及平行自動進退刀車削,夾頭可正逆轉運作及微調進刀

■車、削、切斷、車溝、鑽孔、修內徑、可車內外牙(公英制均可)

■可配合分度盤作齒輪剖銑、齒輪整修等工作

■工作精度可達0.01mm

■整體超輕量,可任意移動至不同工作場所

大型旋盤のコンセプトを基本に、設計した本格小型旋盤です

ミニレースML-360は、豊富なアクセサリーを使用する事により広範囲に精度の高い加工が自由自在に出来ます。

可作斜度及平行自動進退刀車削,夾頭可正逆轉運作,微調進刀,無論車、削、切斷、車溝、鑽孔、修內徑、並可車內外牙(公英制均可)擁有比一般大型車床更具精密的準確度。

FEATURES

SUPERBLY RIGID BED WITH PRECISION GROUND VEEWAYS

- The well located cross bracing and heat treated bed ensure excellent long term rigidity.

POWERFUL 300 WATT MOTOR FOR FORWARD REVERSE ROTATION

- The change of direction is easily achieved on this powerful condenser motor proving convenient for automatic feed and thread cutting.

MAIN SPINDLE FOR PRECISE MACHINING

- The hardened and accurately finished main spindle is supported with precision taper roller bearings.

- Thus steady and long lasting accuracy is secured.

VERSATILE TAIL STOCK

- Dead or Live center fitted in the tail spindle facilitates turning on long workpiece.

- Drilling, reaming and so on are also practicable with Drill chuck.

CARRIAGE OF CENEROUS TRAVEL

- The 85mm cross feed ensures adequate range for both lathe work and milling.

CONVENIENT 0(ZERO) - SETTING

- Feed handles are of coaxial ring construction which permits 0-setting operation.

- Cut depth can be preset and checked easily.

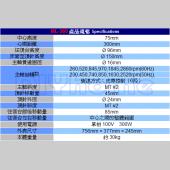

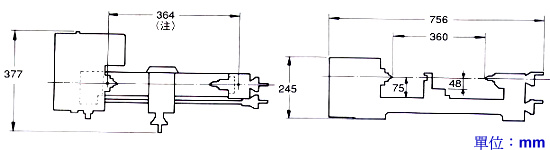

ML-360 產品規格 Specifications 中心高度 75mm 心間距離 360mm 往復台高度 Ø 96mm 床面至頂針高度 Ø 150mm 主軸貫通圓徑 Ø 16mm 主軸回轉数 260,520,845,970,1845,2860rpm(60Hz) 230,450,740,850,1630,2520rpm(50Hz) 變速方式:皮帶控制(6段) 主軸斜度 MT #2 頂針移動量 45mm 頂針外徑 Ø 24mm 頂針斜度 MT #2 往復台前後移動量 85mm 往復台左右移動量 中心之間的整體範圍 使用電源 單相 100V 300W 外表尺寸 756mm × 377mm × 245mm 本體重量 約 30kg ENGLISH JAPANESE

ML-360 Selectiveness Accessories

No.M3501★ 三方卡盤 正爪最大25mm 逆爪最大75mm

No.M3502 四方卡盤 正爪最大25mm 逆爪最大80mm

No.M3505★ 固定頂針 先端角度60° MT #2

No.M3507 回轉頂針 MT #2

No.M3508★ 夾頭組 Ø10mm

No.M3509 筒夾座

No.M3510 彈性筒夾 2~14mm十種規格

No.M3517★ 斜度車刀架 最大移動52mm 左右45°

No.M3511 自動進退刀組 mm:0.2~3.0 inch:10~48

No.M3519 減速開關 可減速至80rpm

No.M3520 三角固定架 最大夾徑50mm

No.M3521 側面固定架 最大夾徑50mm

No.M3523 T槽圓盤 Ø150mm

No.M3580 複式刀架 四角度均可使用

No.M3582 圓駒托架 Ø20mm

No.M3583 圓駒托架 Ø25mm

No.M3573 車床底盤 ★=標準配件

|